The SafetyRobotsManager is developed by W.E.S.T. GmbH

Siemens Industry Software Inc. integrated the SafetyRobotsManager together with W.E.S.T. GmbH in the Process Simulate distribution Version 15.1 and higher.

Base: OEM Partner conntract from August 2020

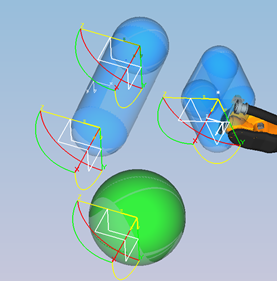

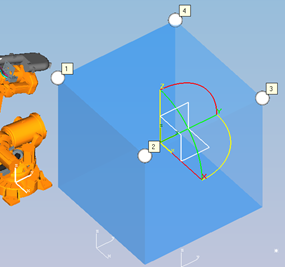

Safety and secured production, going along with the ability to design technical robot safety zones all over the process chain, are an important feature in feasibility studies, when designing new robot production lines or integrating new products in existing robot lines.

Methods integrated in BMW Group, VOLVO CAR CORPORATION, Volkswagen AG, AUDI AG processes

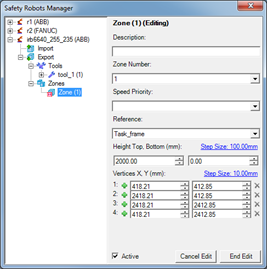

Functions:

- Create, modify and copy of safety zones (Tools and Workspaces)

- Interactive changes in grafic window

- Import of safety zones from different robot-manufactures

- Export of safety zones to different robot-manufactures

Robot Manufactures:

- ABB: SafeMove (RobotWare 5) and SafeMovePro (RobotWare 6)

- KUKA SafeOperation, SafeRange (V2.1, V3.1, V3.2)

- FANUC Mate Controller

Add On features:

- automatic documentation!!

- seamless Industry 4 data exchange to our product RobKalDaT to close the process chain from simulation to reality.

In use at: BMW Group, VOLVO CAR CORPORATION, Volkswagen AG, AUDI AG, KUKA (Holding), ThyssenKrupp System Engineering GmbH, RAITEC Automation GmbH, TMS/Valiant, EKS InTec GmbH, EBZ SysTec GmbH, Konstruktionsbüro Bayer, MAGNA STEYR Fahrzeugtechnik, RW SWISS, VDL Steelweld, TerraNova Automation Engineering GmbH, skiba design PartG, IT8, HLS Group, EDAG PS, TSI Belgium, ATEC GmbH, F.EE Industrieautomation, Ventcon GmbH, CAD engineering s.r.o. INTROSYS SA, EZ Engineering GmbH, Robworld GmbH, RTB GmbH, FFT Produktionssysteme, Comau S.P.A., Dalian Auto Tech IC, TATA Technologies, ProPoint,

Ingenieurdienstleistungen und Consulting auf höchsten Niveau

Ingenieurdienstleistungen und Consulting auf höchsten Niveau